|

Electrical Spec. |

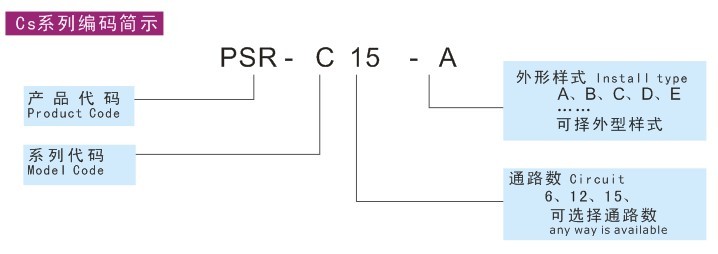

Options | ||

|

Circuit |

15 |

Support for higher speed:500Rpm |

|

|

Rating voltage |

240VAC |

More install method for option |

|

|

Rating current |

2A/Ring,5A,10A by parrelled |

Lead length can be appointed |

|

|

Insulation resistance |

1000MΩ@500VDC |

Cable Exit is optional |

|

|

Dielectric strength |

600VDC@50Hz |

Available connecter and Heat-shrink tube |

|

|

Electrical noise |

10mΩ@6VDC,50mA, 5Rpm |

|

|

|

Mechanical Spec |

Environment |

||

|

Speed |

300Rpm |

Working temperature |

-40℃~+80℃ |

|

Torque |

0.01N.M |

Mechanical vibration |

MIL-SID-810E |

|

Seal class |

IP54 |

Humidity |

10% to 90% RH non-condensing |

|

Contact material |

Precious Metal:Gold-Gold |

Materials |

Lead Free,RoHS compliant |

|

Lead Wire |

15 color AWG#28 Teflon wire |

CE Certified |

YES |

|

Life |

30million revolutions |

|

|

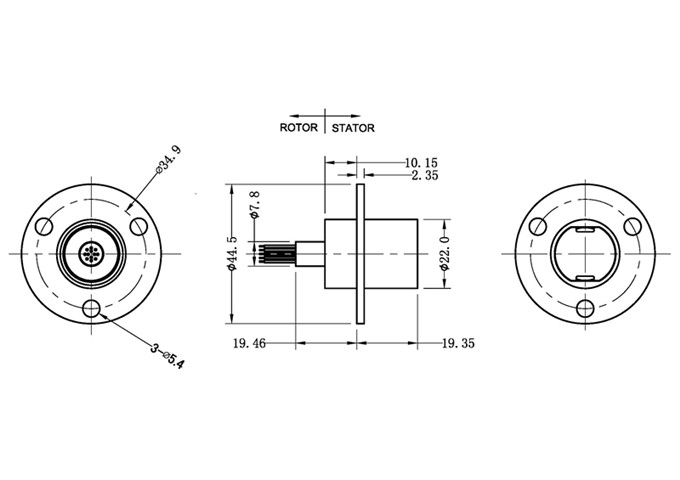

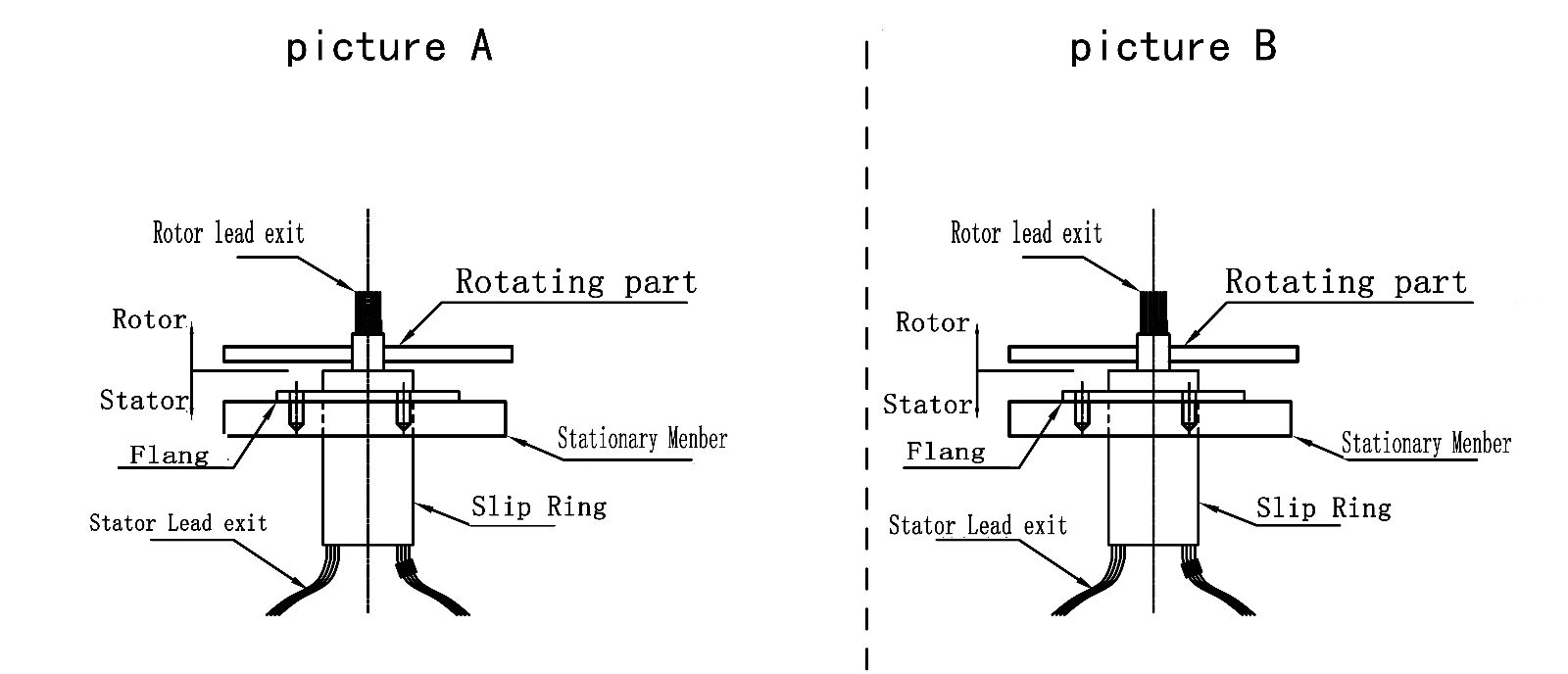

Installation Guide,

Picture A,

1. Position the slip ring in the desired location and tighten both set screws to the shaft . Maximum torque 25 Ib-in(DO NOT OVER TORQUE)

2. Route the wiring and make the neccessary connections . Do not allow the wiring to restrict free rotation of the slip ring . Do not constrain wiring such that wire flexing occurs . Doing so will ultimately cause failure(breakage of the wiring)

Picture B

1.Align the mounting holes(M3×8) in the flange to mounting base and install mounting screws(M3), securely tighten screws.

2. Route the wiring and make the neccessary connections . Do not allow the wiring to restrict free rotation of the slip ring.

CAUTION:

Because of possible geometric mismatching between the customer's application and the slip ring , 'hard mounting' of both ends of the slip ring (i.e.,securing the rotor and stator such that threr is no floating during operation) is not recommended and may cause premature failure.