|

Electrical Spec. |

Options | ||

|

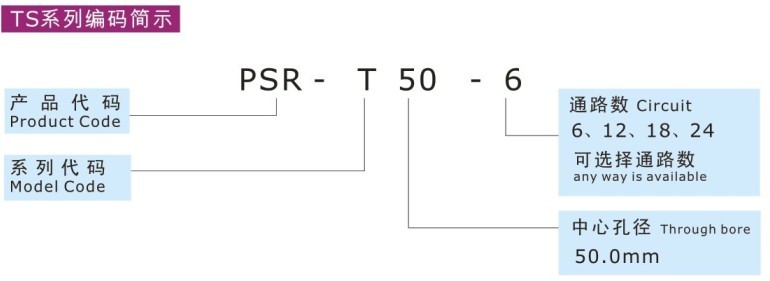

Circuit |

6-246 |

Flange for set up |

|

|

Rating voltage |

380VAC |

The wire exit direction,length is optional |

|

|

Rating current |

5A /Ring,10A /Ring,15A /Ring |

Can combine more circuits:1-246Ring |

|

|

Insulation resistance |

1000MΩ@500VDC |

Higher voltage and current capacity |

|

|

Dielectric strength |

600VDC@50Hz |

Higher rotational seed:1000Rpm,2500Rpm,5000Rpm,10000Rpm |

|

|

Electrical noise |

10mΩ@6VDC,50mA, 5Rpm |

|

|

|

Mechanical Spec |

Environment |

||

|

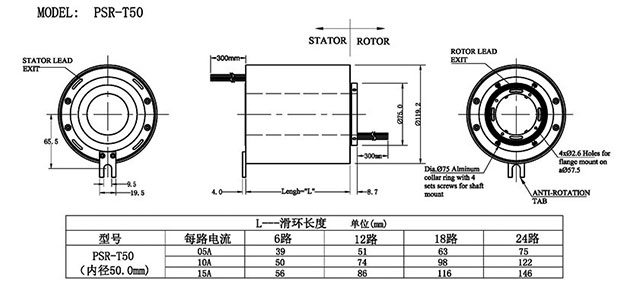

Through bore |

50mm |

Working temperature |

-40℃~+80℃ |

|

Speed |

300Rpm |

Mechanical vibration |

MIL-SID-810E |

|

Torque |

40N.cm |

Humidity |

10% to 90% RH non-condensing |

|

Seal class |

IP54 (IP68Options) |

Materials |

Lead Free,RoHS compliant |

|

Contact material |

Precious Metal |

CE Certified |

YES |

|

Lead Wire |

12 color Teflon wire |

|

|

|

Life |

30million revolutions |

|

|

|

¤ Feature

♦ Fiber brush technology provides maintenance free opration-no cleaning or lubrication required

♦ Moudel design ;Meet the most of requirement

♦More install method for opdation

♦Can combine signal and power in same slio ring ♦ Can combine more circuits :1-100Ring |

|

|

¤ Typical

1. Silicon furnace 2. CCTV Monitoring System 3. Eletrical test equipment 4. Medical equipment 5. Robotics

|

|

Installation Guide:

|

|

|

CAUTION: Because of possible geometric mismatching between the customer's application and the slip ring,'hard mouting'of both ends of the slip ring(i.e.securing the rotor and stator such that there is no floating during operation) is not recommended and may cause premature failure. |

|